There must be a certain gap between the brake shoes and the brake drum. If the gap between the shoes does not meet the requirements, it will directly affect the braking performance of the car. If the shoe gap is too large, the braking hysteresis time increases, the braking distance increases, and the safety of the car is reduced; if the shoe gap is too small, the braking cannot be completely released, which increases the driving resistance and accelerates the speed of the brake drum. Wear of the shoe. If the gap between the brake shoes of each wheel is inconsistent, the braking deviation will occur, which will also affect the driving safety. Therefore, after the vehicle is maintained, the shoes are updated, and the brakes are repaired, the shoe clearance should be

1 Adjustment of air brake shoe clearance

The adjustment of the brake shoe clearance is divided into simple adjustment and comprehensive adjustment. Only by turning the adjusting worm to change the gap of the shoe is called simple adjustment; by adjusting the worm of the adjusting arm and the fulcrum pin to achieve the gap of the shoe, it is called comprehensive adjustment. In normal vehicle use, only simple adjustments can be made to meet the requirements, but when the simple adjustments cannot meet the requirements, comprehensive adjustments should be made.

The adjustment of the shoe clearance must be carried out after the tightness of the hub bearing is adjusted.

1) Simple adjustment

①Set up the axle so that the wheels can rotate freely.

②Use the specified thickness gauge to check the gap at the upper and lower ends of the shoe.

③ Rotate the worm on the brake arm, as shown in Figure 2. Adjust the upper end clearance, the front wheel rotates the worm clockwise, the clearance becomes smaller, and vice versa increases; the rear wheel rotates the worm counterclockwise, the clearance becomes smaller, and vice versa increases. When adjusting, pull the thickness gauge repeatedly, when you feel a slight resistance, it is suitable. When the gap is adjusted, if there is still a slight friction sound between the friction plate and the brake drum, it is allowed to slightly enlarge the gap.

2) Comprehensive adjustment

①Add up the axle to make the wheels turn freely.

② Loosen the locking screw of the fulcrum pin of the shoe sign, turn the fulcrum pin, make the lower end of the shoe close to the brake drum, and then turn the brake arm to adjust the worm, so that the upper end of the shoe comes close to the brake drum. Repeat this adjustment until the upper and lower ends of the two shoes are in full contact with the brake drum, and the brake drum cannot rotate.

③Turn the brake arm to adjust the worm, so that the friction plate is out of contact with the brake drum, and there is a gap, and use the thickness gauge to check the gap between the upper and lower ends. If the clearance at the lower end is not suitable, you can turn the fulcrum pin a little, and cooperate up and down until the clearance meets the requirements.

④Tighten the fulcrum pin fixing nut.

In the actual adjustment process, sometimes there is a large gap on one side and a small gap on the other side. At this time, for the front wheel brake, the three fixing screws on the camshaft bracket can be loosened, and for the rear wheel brake, the fixing screws on the brackets at both ends of the camshaft can be loosened, and then the camshaft can be knocked with a hammer to reach the gap. The big side is close. If there is still no effect after doing this, you can also put an iron sleeve on the contact part between the shoe and the cam on the side with a large gap, and insert iron pieces of different thicknesses into the iron sleeve for adjustment.

(2) Adjustment of the wheel brake of the hydraulic brake device.

2 The specific adjustment steps and methods are as follows.

①Support the axle so that the wheels can rotate freely, and loosen the fulcrum pin fixing nut.

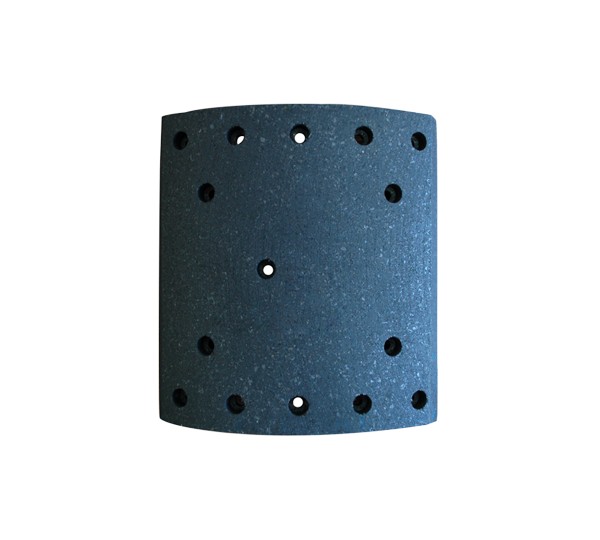

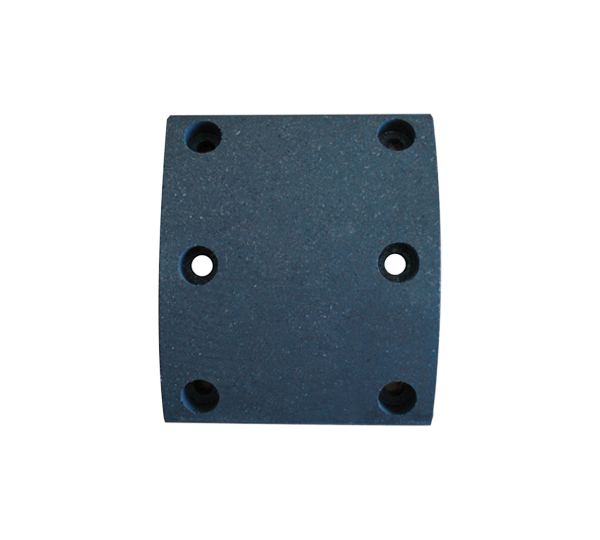

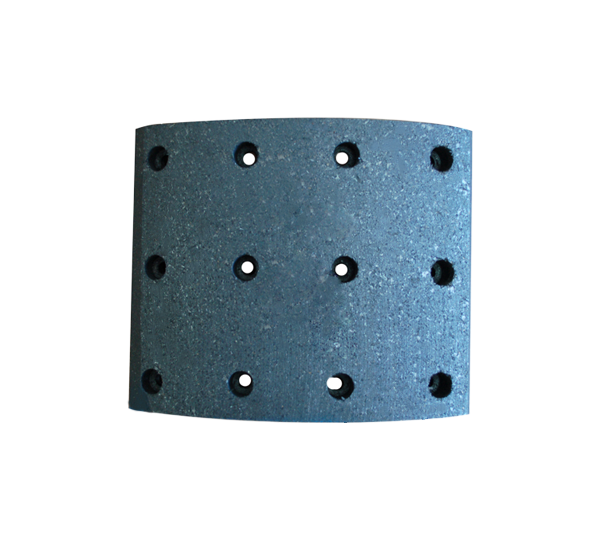

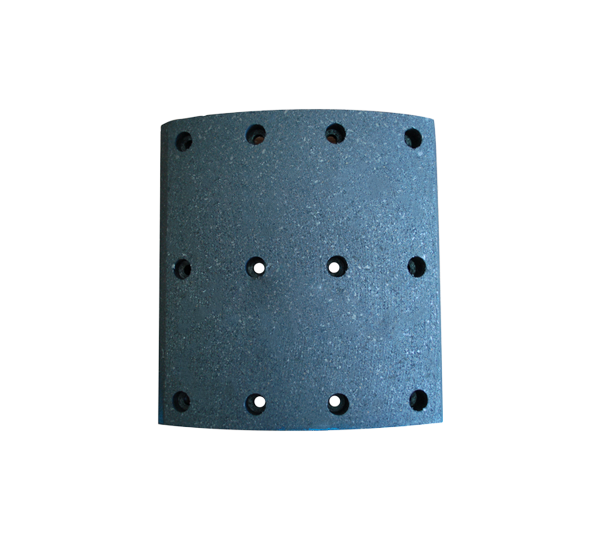

②Turn the fulcrum pin so that the eccentric marks are opposite to each other. At this time, the gap between the lower end of the shoe and the brake drum is the largest.China bus brake pad

③ Rotate the upper adjusting cam in the direction of the arrow shown in Figure 3 to make the upper end of the shoe contact the brake drum and make it difficult to rotate the brake drum.

④Turn the fulcrum pin in the direction of the arrow shown in Figure 3 to make the lower end of the shoe abut the brake drum, and then turn the fulcrum pin back in the opposite direction.

At the half position, the clearance at the lower end of the shoe is equivalent to about half of the original clearance, and the brake drum can still rotate at this time.

⑤Repeat steps ③ and ④ until the upper and lower ends of the shoe contact the brake drum.

⑥Finally, gradually rotate the upper end adjusting cam in the opposite direction, so that there is a slight gap between the upper and lower ends of the shoe, and the brake drum can rotate flexibly, which means that the adjustment is appropriate. When adjusting, it can be measured with a thickness gauge. After adjustment, the fulcrum pin fixing nut should be locked.

When adjusting the shoe clearance at ordinary times, it is generally a simple adjustment, that is, turning the eccentric adjustment cam to make the shoe clearance suitable at high speed.

The front wheel brake of the automobile is a single-curve assist balanced brake, and the adjustment method of the gap of each brake shoe is the same as the above adjustment method.Custom Truck Brake Lining

English

English 中文简体

中文简体