Brake disc rusted:

Many people do not understand why the brake discs rust and they worry that the braking performance will decrease. In fact, most brake discs in family cars are made of cast iron. They do not rust on the body surface and are exposed to sunlight and rain for a long time. The working environment is terrible. Especially when parked for a long time, the surface is easy to generate. rust. In this case, we can also see the new car storage in the 4S shop. These are new cars, but that's what happens if you park outdoors for a long time.

Rust on ordinary brake discs is actually normal and not necessarily related to quality. However, it still has some effect on the braking system, but it doesn't have to be a big move. Owners of these issues can take care of themselves.

If it's only light rust, we can use continuous braking to remove the rust while driving, because disc brakes are braked by friction between the caliper and the pads and can be ground under multiple brakes rust. Of course, go to the security section to do this method. This is the "polish" method for light rust.

If the rust is severe, the above method does not apply. When braking, it also emits noticeable vibrations, such as the brake pedal, steering wheel. This situation has to be treated specially, because rust is too stubborn, and it's more than just polishing. “No, it hardly accelerates the wear of the brake pads. In this case, we need to go to a repair shop to remove the brake disc and clean the rust.

Of course, if the rust is too severe, even a repair shop can't do anything, so owners are often in a situation where they have to maintain the brake discs every two months. In order to avoid severe corrosion of the brake discs, it is also possible to drive on the road at any time.

Whether the brake disc is rusted, what problems should the car brake system pay attention to?

In addition to the rust-like conditions that we can easily see, there are two aspects of brake system inspection that we have to pay attention to. The first is the thickness of the brake pads. The minimum thickness of brake pads is about 2 or 3 mm. Within this limit, it must be replaced. At present, when the brake pads are too thin, many models will prompt the position of the brake warning light, which is convenient for relative self-checking. There is no need to worry about vehicles without brake alerts, as the brake calipers will have protruding positions near their thinnest thickness, producing braking noise to warn the driver.

If it is a drum brake, you can hear the sound of the brake accompanied by the sound of "iron for iron", or check the position of the handbrake becomes high, then the brake pads must be replaced immediately.

Another important consideration for brake system inspections is brake fluid. High-quality brake fluid is critical to safety and brake system performance. For regular brake fluid changes, all brake fluid removed from the system should be discarded and not reused. You should be in the market for better quality brake fluid. If the brake fluid is dirty, let it go and flush the entire system, then fill the master cylinder with new fluid. If you keep using brake fluid for a long time and you keep adding it, then obviously there is something wrong with your braking system and you should get it checked.

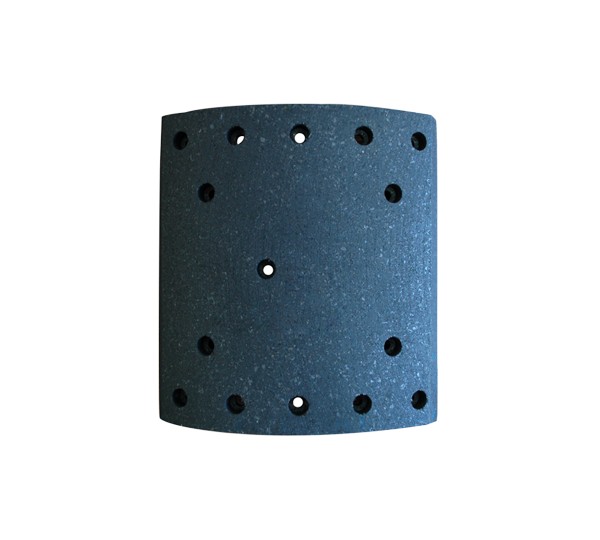

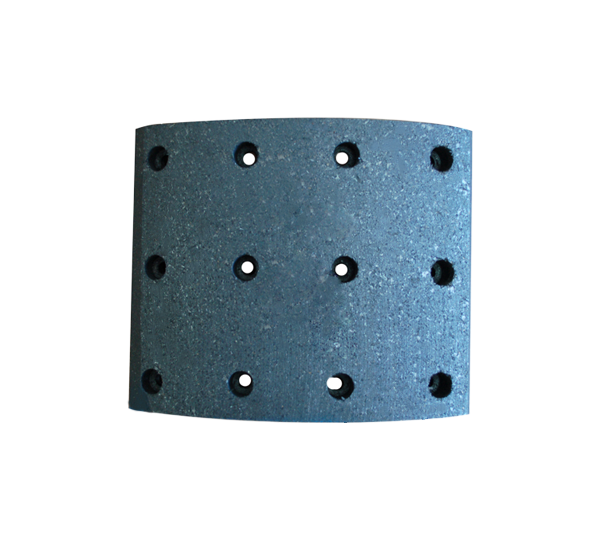

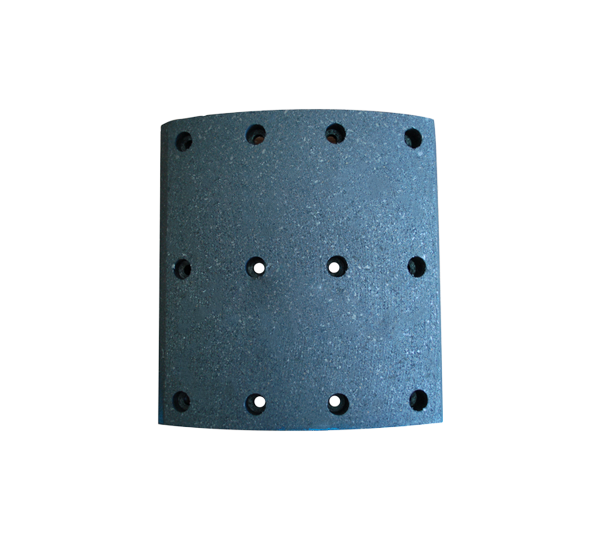

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

English

English 中文简体

中文简体