First of all, it is necessary to check whether the replaced brake pads are genuine accessories, whether the integrity of the product packaging, anti-counterfeiting marks and packaging marks are consistent with the marks on the brake pads, and whether the product model is consistent with the content of the certificate.

Before lifting the vehicle, the cover containing the brake fluid should be opened, and the tire screws should be loosened at the corners. If a simple jack is used for support, the jack should be well supported, and the wheels without replacing the brake pads should be reinforced.

Remove the tire, loosen the tightening screws of the caliper body, and check the screws and the sliding guide rod of the caliper, remove the sediment and oil on it, and apply lubricating oil for maintenance.

Remove the old brake pads and check the brake disc for wear and tear. Serious wear and tear should be replaced with new brake discs with a cycle of 80,000 to 120,000 kilometers, otherwise the wear of the newly replaced brake pads will be accelerated, and the direction of braking will shake and the braking force will be too small.

It is worth noting that when installing new brake pads, the inside and outside should be distinguished, and the friction surface of the brake pads should face the brake disc to make the disc fit properly.

Install the accessories and tighten the clamp body. Before tightening the pliers, a tool should be used to push the plug on the pliers back into place so that the pliers can be installed in place. If you need to replace the brake pads on the drum brake, it is recommended to go to a professional repair shop to ask professionals to operate, so as to avoid mistakes.

The tires should be reset after the brakes are installed. When installing tire screws, tighten them at the corners, which will help protect the tires and brake hubs. At the same time, it is also necessary to check whether the wear of the tread and the edge is normal. It is best to replace the left and right wheels regularly, which will help prolong the service life of the tire.

Finally, the brake fluid needs to be checked. The brake fluid should be replaced and added regularly, and at the same time, it should be ensured that the grade of the brake fluid used is the same as the grade of the original brake fluid, which will help to remove the sludge and dirt in the brake pipeline and make the braking more sensitive. If different grades of brake fluid are used together, chemical changes will occur, resulting in sludge and inorganic salts deposited on the brake system, which will block the pipeline over time and cause brake failure. The consequences are unimaginable.

Before leaving the car, apply force to the brakes until you feel that the brakes have returned to the ideal state, and then you can drive out of position normally.

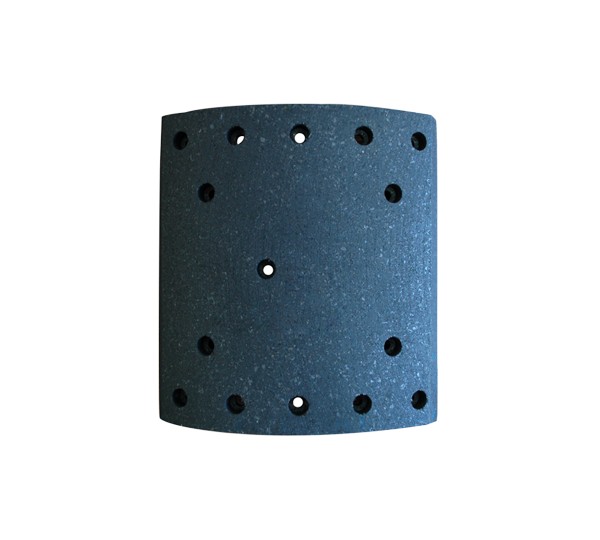

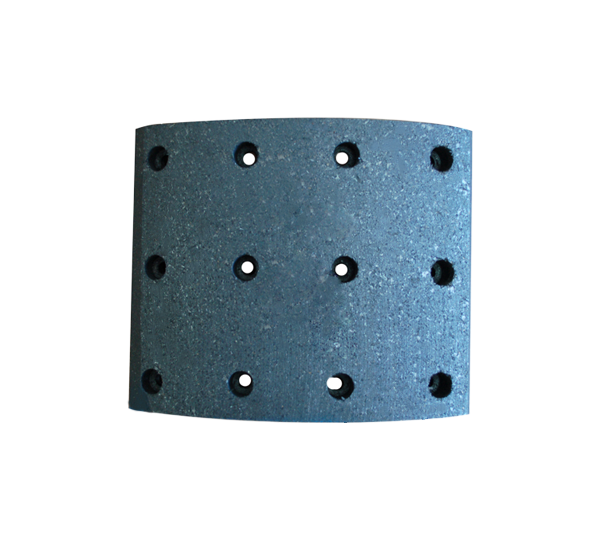

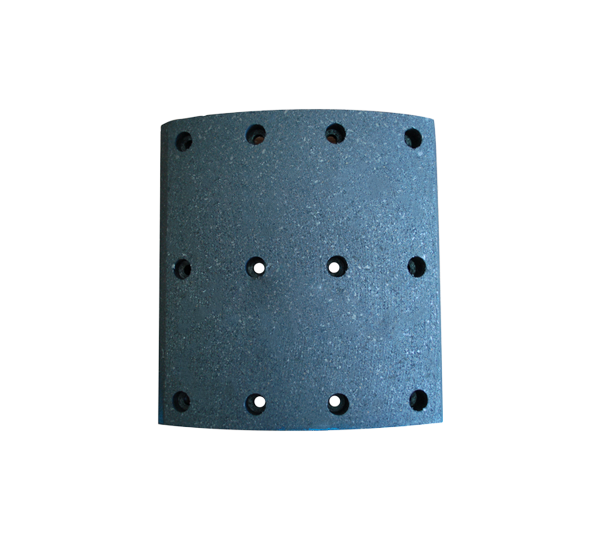

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

PREV:What are the advantages and disadvantages of ceramic brake pads?

NEXT:What is the cause of brake pad burning due to drag grinding?

NEXT:What is the cause of brake pad burning due to drag grinding?

English

English 中文简体

中文简体